Motorcarspecs.com delivers automobile industry news, and its unique content can entice viewers from all over the world. Every day, the Motorcarspecs.com team assists thousands of consumers in conducting vehicle research and comparing pricing on a wide range of automotive products and services. We’ve been pioneering innovative ways for prospective buyers to engage with automobiles and obtain timely and accurate information since January 2020. We created this platform for you, the viewers, to provide an honest evaluation on a relevant automobile, which we will completely review and post on our site.

How a Car Engine Works

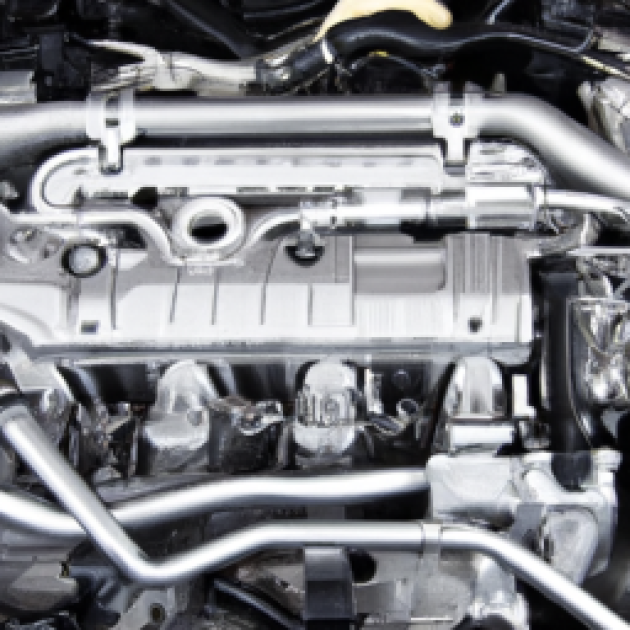

The internal combustion engine is the heart of a car, converting energy from gasoline into mechanical power to turn the wheels. Let’s take a closer look at how a car engine works and how it can be improved.

Basics of Engine Operation

The four-stroke engine is the most common type of car engine. It is composed of the following parts:

- Piston: A cylindrical part located in the cylinder which reciprocates up and down.

- Connecting Rod: This is connected from the piston to the crankshaft.

- Crankshaft: A revolving shaft which is connected to the flywheel, and has a crank attached at one end.

- Flywheel: This is a heavy wheel connected to the crankshaft which stores energy.

- Spark Plug: This is responsible for igniting the fuel/air mixture for combustion.

- Valve: This controls the flow of air and gasoline into the engine cylinders.

Operation Sequence

The operation sequence of a four-stroke engine is as follows:

- Intake Stroke: The piston moves downwards and the intake valve opens, drawing a mixture of air and gasoline into the cylinder.

- Compression Stroke: The piston moves upwards, compressing the air and gasoline mixture.

- Power Stroke: The spark plug ignites the air/fuel mixture and the piston moves downwards, generating power.

- Exhaust Stroke: The piston moves upwards and the exhaust valve opens allowing the spent air and fuel mixture to be expelled from the cylinder.

Improving Engine Performance

The performance of a car engine can be improved by:

- Increasing Compression Ratio: This is the ratio between the volume of the cylinder when the piston is at its lowest point and when it is at its highest point. Increasing the compression ratio increases the power output of the engine.

- Better Fuel Mixture: Using a better fuel mixture with higher octane rating will result in a more powerful engine.

- Replacing Parts: Replacing the spark plugs, air filters and other components with higher performance parts will result in more power.

Conclusion

The internal combustion engine is the source of power and torque in a car. By understanding how it works and how it can be improved, you can ensure your car runs at its best.

What are the main components of a car engine?

1. Cylinders: The cylinders are the main components of an engine that convert fuel and air into mechanical energy.

2. Pistons: Pistons are responsible for moving the air/fuel mixture through the engine and creating pressure that allows the vehicle to move.

3. Spark Plugs: Spark plugs work to ignite the fuel/air mixture inside the cylinders, allowing combustion to take place.

4. Crankshaft: The crankshaft is responsible for turning the pistons and converting the upward and downward motion of the pistons into rotational energy that is used to power the vehicle’s wheels.

5. Camshafts: Camshafts control the valve timing and lift of the engine, allowing air and fuel to enter and exit the cylinders.

6. Timing Belt: The timing belt synchronizes the rotation of the crankshaft and the camshaft, ensuring that each cylinder is supplied with fuel and air at the correct time.

7. Oil Pump: An oil pump circulates lubricating oil throughout the engine, reducing heat and friction caused by the rotating parts.

8. Exhaust System: The exhaust system removes the hot gases produced by combustion. The exhaust system is also responsible for controlling the noise produced by the engine.

What is the purpose of each component in a car engine?

1. Piston: Provides the force that drives the engine by expanding and contracting to push the vehicle’s crankshaft.

2. Crankshaft: Connects the pistons to the transmission, translating their linear motion into the circular motion needed to drive the vehicle.

3. Timing Belt: Links the crankshaft and camshaft to keep them in sync and ensure that the valves open and close at the proper time.

4. Spark Plugs: Ignite the fuel-air mix in the cylinders to generate power.

5. Radiator: Helps keep the engine running at its optimal temperature by dissipating the heat generated by combustion.

6. Oil Pump: Circulates oil through the engine to provide lubrication and cooling.

7. Fuel Injectors: Meter the fuel accurately into the cylinders and ensure an optimal air-fuel mixture for combustion.

The automobile engine is one of the most important inventions of the modern era. Its ability to transform energy into motion has allowed us to move vast distances with ease, something that was previously impossible. So, how does the car engine work?

At the heart of every car engine is a set of pistons that are arranged in one or more rows known as cylinders. Inside each cylinder, a spark plug is used to ignite a fuel and air mixture that has been drawn in from the car intake system. The force from the exploding fuel and air mixture pushes the pistons which in turn turn a crankshaft connected via a flywheel. This up and down motion of the pistons is converted by the crankshaft into a rotating motion which is then transferred to the wheels of the vehicle through a series of gears and a drive shaft.

The car engine needs a constant supply of air, fuel, and spark to keep running. To generate the spark, the car is fitted with an ignition system which is made up of an ignition coil, spark plug, and distributor. The distributor takes the energy from the ignition coil and distributes it to each of the spark plugs at the right time so they can ignite the fuel and air mixture in each cylinder.

To ensure that the engine keeps running at a consistent speed, it is also fitted with a series of sensors and emission control systems. The sensors measure various parameters such as engine speed, air temperature, and exhaust gases and send the data to a centrally located ECU (Engine Control Unit). The ECU then adjusts the amount of fuel and air being drawn into the cylinders and the timing of the spark to make sure everything is running efficiently and safely.

By now it should be clear that the automobile engine is an incredibly complex piece of machinery. Its ability to deliver exact amounts of fuel, air, and spark at the right times, and its ability to convert the energy from explosions into useful motion has enabled us to explore the world in a way that was previously unthinkable.

Why is Design Thinking important?”

What are the benefits of using Design Thinking?

Design Thinking is important because it helps organizations find creative solutions to complex problems. It encourages creativity, innovation, and exploration of alternatives, while also maximizing the efficiency of problem-solving. Additionally, it allows organizations to learn through experimentation, collaboration, and empathy. Design Thinking can provide improved outcomes, better customer experience, and more engaged stakeholders. It encourages teams to think outside of the box, to come up with creative and inventive solutions, which can significantly improve an organization’s ability to face challenges.

How did coal power the Industrial Revolution?”

What advances in technology were necessary to make use of coal in the Industrial Revolution?

In order to make use of coal to power the Industrial Revolution, efficient and large-scale burning of coal must be enabled. This required the development of more efficient steam engines and the use of coal-fired furnaces, both of which allowed for more efficient use of the energy stored in coal. Additionally, invention of the multi-tubular boiler by Thomas Savery in 1698 and later developments of this by Thomas Newcomen in 1712 enabled the steam engine to produce enough heat and pressure to drive an industrial steam engine. All of these technological developments allowed for the harnessing of the energy stored in coal which powered the Industrial Revolution.